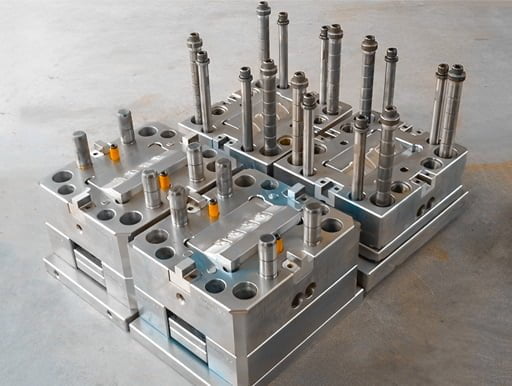

Insert Molding

Custom Insert Molding Solutions

Inman Molding & MFG stands at the forefront of insert molding solutions, offering a comprehensive range of capabilities tailored to meet the diverse needs of our clients. With our state-of-the-art equipment and skilled technicians, we specialize in molding metals to plastics, plastics to plastics, ceramic to plastics, and even specialty wire harnesses. Our horizontal and vertical shuttle equipment allows us to achieve precise results across a wide range of materials and configurations, ensuring exceptional quality and performance in every project.

![]()

Molding Metals to Plastics

Insert molding of metals to plastics is a specialized process that involves molding metal components into plastic parts. At Inman Molding & MFG, we have the expertise and equipment to seamlessly integrate metal inserts into plastic components, creating robust and durable assemblies. Whether you need threaded inserts, metal fasteners, or other metal components embedded within plastic parts, our skilled technicians can deliver superior results with precision and efficiency.

Plastics to Plastics Insert Molding

Plastics to plastics insert molding is another area of expertise at Inman Molding & MFG. This process involves molding one plastic component into another plastic part, creating a seamless and integrated assembly. Our advanced equipment and precise techniques allow us to achieve tight tolerances and intricate geometries, ensuring that each part fits together perfectly. Whether you need overmolding, encapsulation, or other plastics to plastics insert molding solutions, we have the capabilities to meet your needs with precision and accuracy.

Ceramic to Plastics Insert Molding

In addition to metals and plastics, we also specialize in insert molding ceramic components into plastic parts. This process combines the strength and durability of ceramics with the versatility and cost-effectiveness of plastics, resulting in high-performance assemblies for a wide range of applications. Our advanced equipment and expertise allow us to achieve tight tolerances and complex geometries, ensuring that each ceramic insert is securely bonded to the plastic substrate for optimal performance and reliability.

Specialty Wire Harnesses

At Inman Molding & MFG, we understand the importance of specialty wire harnesses in various industries, from automotive to electronics. Our insert molding capabilities extend to the integration of wire harnesses into plastic components, providing a seamless and durable solution for your electrical assembly needs. Whether you require complex wiring configurations, strain relief features, or other custom requirements, our skilled technicians can design and mold wire harnesses to meet your exact specifications.

Horizontal and Vertical Shuttle Equipment

Our insert molding capabilities are further enhanced by our horizontal and vertical shuttle equipment. These advanced machines allow us to achieve precise results across a wide range of part sizes and configurations, from small, intricate components to large, complex assemblies. With horizontal shuttle equipment, we can efficiently mold multiple parts in a single cycle, reducing production time and cost. Vertical shuttle equipment enables us to mold parts with vertical inserts, providing flexibility and versatility in design and production.

Quality Assurance

At Inman Molding & MFG, quality is our top priority. We adhere to strict quality control measures throughout the insert molding process, from material selection to final inspection. Our skilled technicians monitor every aspect of production to ensure that each part meets the highest standards of excellence. With our commitment to quality assurance, you can trust that your insert molded parts will be reliable, durable, and built to last.

Industry-Leading Expertise

With decades of experience in the injection molding industry, we have earned a reputation for excellence and reliability. Our team of skilled technicians and engineers has the knowledge and expertise to tackle even the most challenging projects. Whether you're in the healthcare, automotive, defense, HVAC, electronics, or any other industry, you can trust Inman Molding & MFG to deliver precision injection molding solutions that meet your exact specifications.

Customer Satisfaction

At Inman Molding & MFG, customer satisfaction is our top priority. We believe in building long-lasting relationships with our clients based on trust, transparency, and reliability. From the initial consultation to the final delivery, we strive to provide exceptional service and support every step of the way. Our dedication to customer satisfaction is what sets us apart and drives us to continuously improve and innovate.

Contact Us Today

Are you ready to experience the difference that precision injection molding can make for your project? Contact the experts at Inman Molding & MFG today to discuss your needs and discover how we can help bring your vision to life. With our advanced capabilities, industry-leading expertise, and unwavering commitment to quality, you can trust Inman Molding & MFG to deliver superior results every time.